Precision in Every Measure

Elevate Your Experience with Our Weighing and Packaging Solutions

Search For Products

Product Categories

Linear Feeder Packing Machine

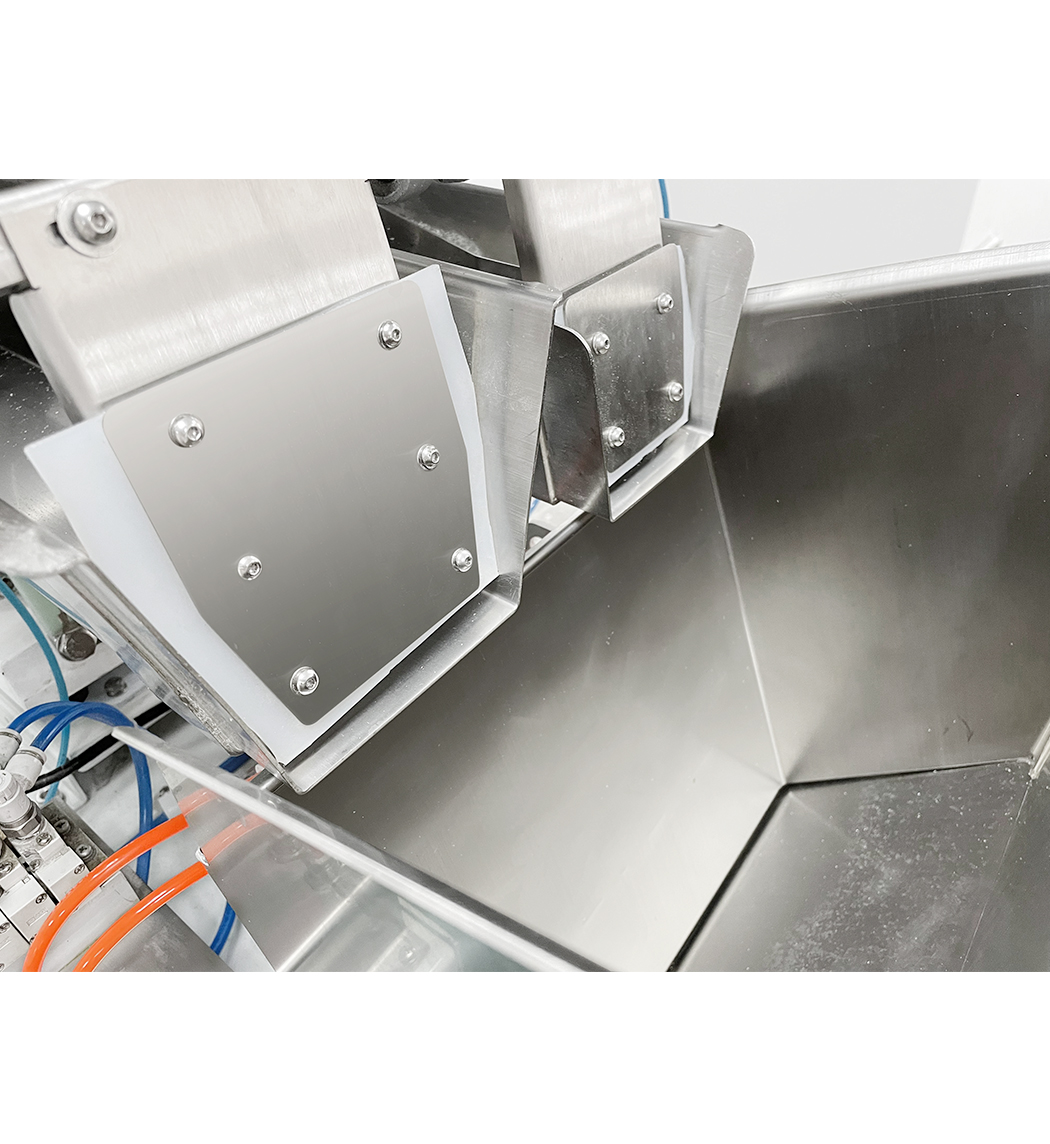

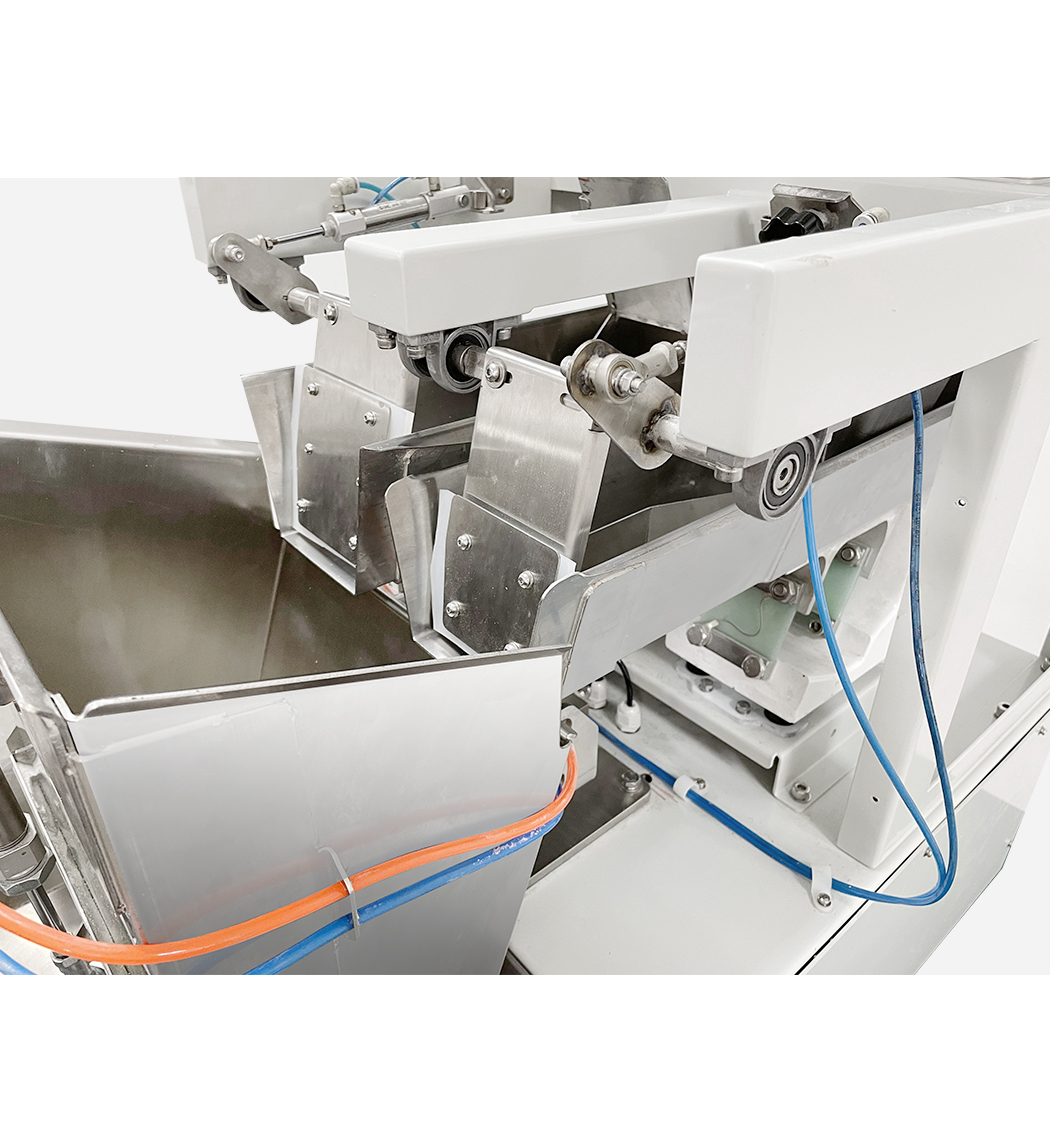

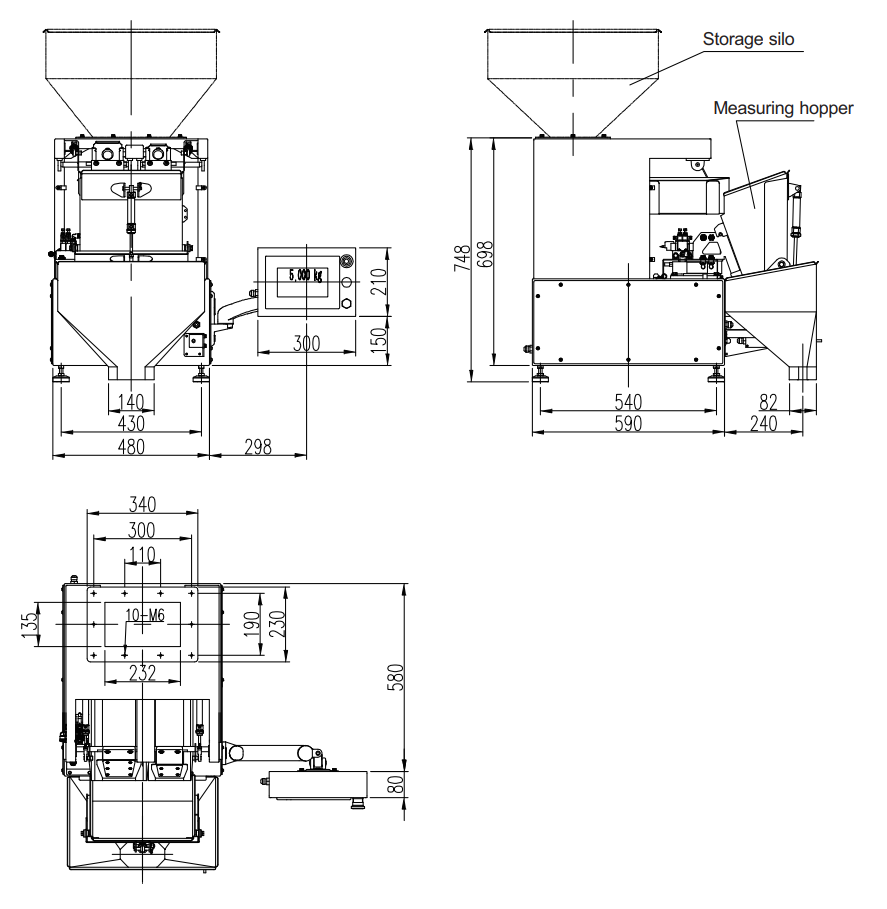

Prompt Linear Feeding Packing Machine is designed to measure powder and granular materials. The machine has a multi-stage feeding feature which can be put to use under controlled vibration. Its pneumatic cylinder ensures fast discharging in accordance with the packing speed. The weighing range of this linear feeder machine is vast enough to serve various industrial packaging requirements. Its high level of precision ensures accurate packaging and measurement for agro, food, fodder, chemical, plastic, rubber, and other industries.

Product Function

- Automatic weighing type dosing function

- Two-speed vibration feeding control

- Automatic zeroing function

- Process control, automatic parameters correction function

- Accumulation and statistics function

Product Features

- Intelligent: only need to set the target value, LF-5K can automatically adjust the optimal dosing speed with the guarantee of accuracy

- Easy installation: standard external flange interface

- Data export: USB interface, convenient for data export

- Simple operation: 7-inch touch screen

- High speed and high precision: double vibrators for feeding, fast and accurate.

| Model | LF-5K | |

| Powder | AC220V±10%, 50/60Hz, 120W | |

| Weighing Range | 0.25~5kg | |

| Weighing Accuracy | ±2~5g | |

| Feeding Speed | ≤900pcs/hour | |

| Measuring Hopper Volume | 8L | |

| Working Temperature | 0 ~ 40°C | |

| Max Humidity | 90% R.H Condensation must be avoided | |

| Pneumatic | 0.4~0.6MPa 2m3/h |

FAQ

Clearing Up Your Queries and Providing Informed Solutions

What is the Prompt Automatic Bag Filling System?

The Prompt Automatic Bag Filling System is a high-speed bag filling machine designed for industrial applications that deal with granular products like rice, pulses, animal feed, maize, soybeans, seeds, plastic granules, etc for filling and Stiching/Sealing Bag.

What are the different models available in the Prompt Automatic Bag Filling System?

The different models available in the Prompt Automatic Bag Filling System are PAB-05K, PAB-25K, PAB-50K, and PAB-100K.

What is the accuracy range of the Prompt Automatic Bag Filling System?

The accuracy range of the Prompt Automatic Bag Filling System is ±5gm up to 5kg, ±10gm up to 25kg, ±20 g up to 50 kg and ±50 g up to 100 kg.

What is the speed range of the Prompt Automatic Bag Filling System?

The speed range of the Prompt Automatic Bag Filling System is up to 14 bags per minute for 25kg bagging.

What is the filling mode of the Prompt Automatic Bag Filling System?

The filling mode of the Prompt Automatic Bag Filling System is with a Servo motor with three stages of feeding, course, moderate, and fine.

What is the communication interface available with the Prompt Automatic Bag Filling System?

The communication interfaces available with the Prompt Automatic Bag Filling System are USB, RS232/485, and Modbus TCP/IP.

What is the data storage capacity of the Prompt Automatic Bag Filling System?

The data storage capacity of the Prompt Automatic Bag Filling System is 700,000 bags data.

What is the value for the minimum division in the Prompt Automatic Bag Filling System?

The value for the minimum division in the Prompt Automatic Bag Filling System is 1, 2, 5, 10, 20, and 50.

What is the material used in the construction of the Prompt Automatic Bag Filling System?

The food contacting material used in the construction of the Prompt Automatic Bag Filling System is SS304 stainless steel, and the others are MS.

What is the operating temperature range of the Prompt Automatic Bag Filling System?

The operating temperature range of the Prompt Automatic Bag Filling System is 0°C~40°C.

What is the operating humidity range of the Prompt Automatic Bag Filling System?

The operating humidity range of the Prompt Automatic Bag Filling System is 90% R.H, and condensation is not allowed.

What is the power requirement of the Prompt Automatic Bag Filling System?

The power requirement of the Prompt Automatic Bag Filling System is 3 phase, AC 110 ~ 260V.50/60Hz. Approximate 200VA.

What are the optional accessories available with the Prompt Automatic Bag Filling System?

The optional accessories available with the Prompt Automatic Bag Filling System are double thread, auto thread cutter Stitching machine, and heat sealing Machine.

What is the structure of the Prompt Automatic Bag Filling System?

The structure of the Prompt Automatic Bag Filling System includes a weighing hopper, Storage hopper, electric cabinet, and discharge hopper, Clamper, Conveyor, Stitching machine / Heat-sealing machine.

What is the controller used in the Prompt Automatic Bag Filling System?

The controller used in the Prompt Automatic Bag Filling System is a touch screen bagging controller.

What is the Electronics hardware used in the Prompt Automatic Bag Filling System?

The hardware used in the Prompt Automatic Bag Filling System includes a 10-inch touch screen, actuator, F301 mainboard, and 4G signal transmitter (optional), Stepper Motor, Pneumatics etc.

What are the benefits of using the Prompt Automatic Bag Filling System?

The benefits of using the Prompt Automatic Bag Filling System include high-speed and accuracy with auto feedback control, easy and fast installation, customization for different materials, user-friendly touch screen, and efficient.

What are the advantages of using Prompt Automatic Bag Filling System?

Increased efficiency, consistency, and reduced labor costs.

For which products can this be used?

Granular products

How does Prompt Automatic Bag Filling System handle bag sealing?

Stitching and heat sealing

RELATED PRODUCTS

Prompt Is a leading manufacturer of electronic weighing scales

CASE STUDY

Real-World Success Stories

An Automatic Weight Checking Solution for Dairy Industry.

Check Weighing Machine – Case Study

Prompt Equipments is serving people for over four decades now and wishes to carry this service as a legacy in the years to come.

Read More

Delivering smart checkweigher solutions for improved packaging of electrical products

Online checkweigher – Case Study

Prompt Equipments is serving people for over four decades now and wishes to carry this service as a legacy in the years to come. We provide innovative solutions to some of the biggest manufacturers in India.

Read More