Precision in Every Measure

Elevate Your Experience with Our Weighing and Packaging Solutions

Search For Products

Product Categories

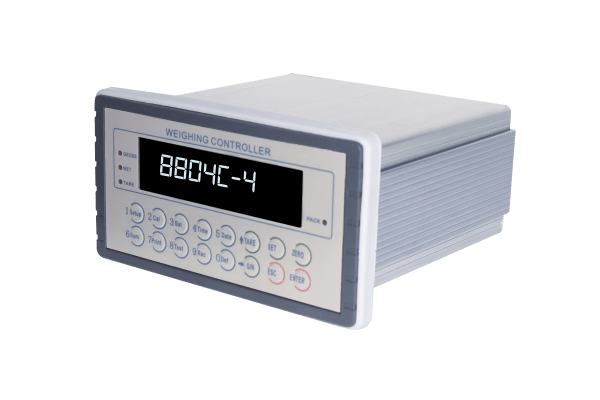

GM8804C-4

This weighing controller is specially designed for loss in weight application. It is an integrated multi-function packing indicator that will control the packing equipment. It has a strong and reliable body, durables in all industrial environment and offers high accuracy. This weighing controller is ideal for feed, chemical, construction and food industries.

- Working with or without a material hopper

- 20 On/Off data input and output control (8 in and 12 out), and all the input/output are user programmable

- Automatic feeding control of three-way asynchronies feeding speed, and the optional “jog feeding” function makes the man-machine interface more friendly

- All the calibration can be manually done by setting millivolt data through the front panel(instead of calibration using actual load or weight)

- 40 recipes can be programmed and stored within this controller for future choice and use

- Leading value for slow feeding is adjustable

- Free fall adjustment

- Multilevel of digital filter are used for reliability

- Batch number setting

- Bag-patting function is provided for powder material

- Automatic Zero-Tracking

- Date and time function

- Provides two serial communication ports to the users to communicate with computer, printer and/or a second display

- Software is specially designed for loss in weight application

- IP65 protected

- High accuracy

- Automatic free fall adjustment

| General Specifications | GM8804C-4 | |

| Power Supply | A C 90 V- 2 6 0 V 50H z / 60H z ±2% | |

| Power Supply Filter | Installed inside | |

| Working Temperatures | -10~ 40℃ | |

| Max. Humidity | 90% R.H without dew | |

| Power | 15W | |

| Dimension | 168×165×82mm | |

| Analog Input Part | ||

| Power Source for load cell | DC 12V 380 mA(MAX) | |

| Input Resistance | 10MΩ | |

| Zero Point Adjustment range | 0.2 ~ 20 mV ( When the transducer is 2 mV / V. ) 0.2 ~ 30 mV ( When the transducer is 3 mV / V. ) |

|

| Maximum Input sensitivity | 0.5μV / d | |

| Input Range | 0.2 ~ 27 mV ( When the transducer is 2 m V / V. ) 0.2 ~ 37 mV ( When the transducer is 3 m V / V. ) |

|

| A/D Type | Sigma – Delta | |

| A/D Rate | 120Times/Second | |

| Non-Linear | 0.01% F.S | |

| Gain Drifting | 10PPM/℃ | |

| Maximum Accuracy of Display | 1/30000 | |

| Digital part | ||

| Display | High light VFD main display and 4 green LED indicators | |

| Negative Display | “—” | |

| Over Scale Display | “OFL” | |

| Key Pad | 16 beep keys |

FAQ

Clearing Up Your Queries and Providing Informed Solutions

What is a weighing controller?

A weighing controller is a device that is used to control and manage the weighing process. It is responsible for receiving and processing signals from the load cells or sensors and providing output signals to other devices.

What is a weighing indicator?

A weighing indicator is a device that displays the weight of the load on the weighing scale. It is typically used in conjunction with load cells or sensors to accurately measure the weight of objects.

What is a weighing transmitter?

A weighing transmitter is a device that converts the signal from load cells or sensors into a standardized signal that can be used by other devices, such as a computer or a PLC.

What are load cells?

Load cells are transducers that are used to measure weight. They convert the force exerted by a load into an electrical signal that can be measured and analyzed.

What is calibration?

Calibration is the process of adjusting a weighing system to ensure that it provides accurate and reliable measurements. It involves comparing the system's readings to a known standard and making adjustments as necessary.

Why is calibration important?

Calibration is important to ensure that the weighing system provides accurate and reliable measurements. A poorly calibrated system can lead to incorrect measurements, which can have serious consequences in industries such as healthcare, pharmaceuticals, and food production.

What is zero drift?

Zero drift is a phenomenon in which the zero point of a weighing system shifts over time. This can be caused by changes in temperature, mechanical wear, or other factors.

What is the difference between analogue and digital weighing systems?

Analogue weighing systems use analogue signals to transmit data, while digital weighing systems use digital signals. Digital systems are generally more accurate and reliable, and can provide more advanced features and functionality.

What is the difference between a single point and multi-point weighing system?

A single point weighing system uses a single load cell to measure the weight of an object, while a multi-point weighing system uses multiple load cells. Multi-point systems are typically more accurate and reliable, but also more complex and expensive.

What are the different application of weighing controller?

● Tank / silo weighing ● Process weighing ● Peak weighing ● Batch weighing ● Bagging system, Check weighing ● Loss-in weight ● Weigh feeder ● Continuous weighing and Dosing ● Liquid Filling ● Weighing and Blending

What are the different Models of Weighing Controller?

M02, GMT-P1, GMT-X1, GM7702, GM8804C-2, M04, GM9907, GM8804C-A6, GM8804C-6, GM8804C-7 etc.

How can we select the Weighing Controller model?

Model selection depends on the application, Process flow, Number of Input and output required, Communication protocol requirement, Speed and accuracy requirement.

What types of mounting is available in controller?

Panel mount , DIN Rail Mount , Field Mount

Is there any Touch Screen Model available?

Yes we have 9907 Series weighing controller having touch screen interface.

Is there any TFT display Model available?

Yes we have M04 Series Weighing controller having TFT display.

Is there any VFD Display Model available?

Yes we have a GM8804C series having VFD display.

Is there any model who can control dual hopper application?

Yes we have GM8804CD, M04 D and GM9907LD model who can control dual hopper application.

RELATED PRODUCTS

Prompt Is a leading manufacturer of electronic weighing scales

CASE STUDY

Real-World Success Stories

An Automatic Weight Checking Solution for Dairy Industry.

Check Weighing Machine – Case Study

Prompt Equipments is serving people for over four decades now and wishes to carry this service as a legacy in the years to come.

Read More

Delivering smart checkweigher solutions for improved packaging of electrical products

Online checkweigher – Case Study

Prompt Equipments is serving people for over four decades now and wishes to carry this service as a legacy in the years to come. We provide innovative solutions to some of the biggest manufacturers in India.

Read More